Get to know your wind farm with retrofit control solutions

You know how much power your wind farm is producing, and you know the tariffs coming in to a dime. You’ve calculated the LCOE, and you carefully track O&M costs. But what about the stuff that’s going on inside the turbines? How much do you know about that? Do you have exact data on topics like the pitch scheduling, drive train performance, temperature developments etc.? In fact, how well do you know your wind farm?

Retrofit control solutions give you the data you need

There are at least two good reasons why you should have access to this data. First and foremost, it’s your wind farm; you should be able to get full performance data about it, too. Yet very often, OEM turbine control solutions only provide performance or high-speed failure data at an extra cost to you—or they cannot give you access to this data at all because the original control architecture is outdated. However, you need this data to increase AEP and lower O&M costs, and that’s the second reason why you should have access to it: Not only is the data yours; it can also help you optimize production. This is particularly important when your wind farm approaches EoW or EoL and you need to increase AEP while extending asset lifetime as much as possible.

Opting for a retrofit control solution from a third-party vendor such as DEIF helps you reach all of these targets. When the original factory-fitted OEM offering does not give you access to the data you need, replace it with a solution that does. It’s a simple matter of letting technology advances work for you. Remember how much mobile phones have changed over the last couple of decades? Upgrading your wind farm control solution is the wind industry equivalent of swapping your museum-worthy Nokia 3310 for the newest iPhone. If your wind farm is just a few years old, chances are that control technology has improved drastically since it was commissioned.

Optimize O&M and increase AEP

How exactly does that help you? Let’s take a couple of examples. First, identical turbines on the same wind farm often perform differently because of topographical conditions and wake effects, and they are subject to varying degrees of wear. With a retrofit control solution, you can get detailed data about all important parameters in each turbine, and you can therefore distribute loads more evenly or schedule turbine service and maintenance on an as-needed basis. This can help you drive down O&M costs and prevent costly downtime.

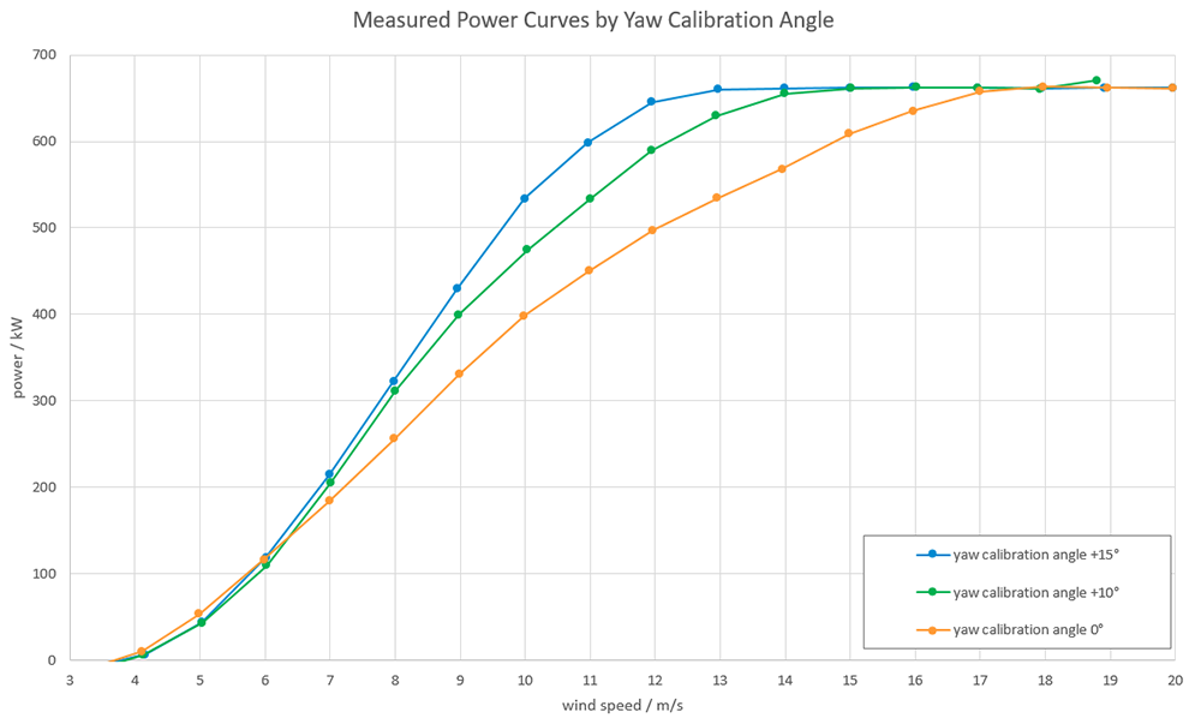

Second, upgrading your wind farm with a state-of-the-art retrofit control solution can also improve AEP. With performance data and advanced control algorithms, your wind turbines can be continuously optimized to the given operating conditions, for example through optimized pitch control or yaw offset calibration. This gives you improved performance across the power curve without reblading or replacing your turbines.

Increased AEP and lower O&M costs mean that the cost of a retrofit project can often be recovered within a few years. As you may be able to extend turbine lifetime by a decade, investing in retrofit control solutions for wind farms approaching EoW or EoL is a financially sound proposition. You can put off major replacement investments for years, make the most of your original CAPEX and achieve a favourable LCOE. With performance data from a retrofit control solution, you can also carry out advanced data analytics and simulation modelling that allow you to make informed lifetime assumptions and plan exactly when it will be time for major overhauls or turbine replacement.

Tailor-made solutions for all major turbine brands

In a digital age where business decisions and performance optimizations are increasingly informed by data analytics, you should have full access to the raw data that makes it happen. At DEIF, we give our customers full, unrestricted access to all of the data generated by our retrofit control solutions, with full SCADA integration and at no extra cost, helping you overcome lower tariffs and tough competition.

We offer tailor-made solutions for all major wind turbine brands and models (e.g. V47 and MM82/MM92)—and all actual site and operating conditions. Your investors will want to know if a retrofit solution will improve turbine condition and safeguard long-term operation. With decades of experience, we have the data to prove that retrofit control solutions have helped wind farm operators. When you select a DEIF solution, you will have that data, too, allowing you to chase down those elusive improvement percentages, achieve increased AEP, a favourable LCOE and fast ROI for your wind farm.

Talk to us about getting the data you really, REALLY need

DEIF is a family-owned company headquartered in Denmark, sometimes referred to as the wind power capital of the planet. Our family of partners and customers is truly global, though, and we are active in many markets around the world. Contact us for a chat about your options for retrofit control solutions that give you the data you need to really, REALLY get to know your wind farm.

We look forward to helping you!