Change management: the key to successful EMS implementation

Successfully implementing an energy management system (EMS) on a ship requires careful change management tailored to the organisational structure of the company and crew.

This was one of the main conclusions of a recent graduation project written by a bachelor student at DEIF.

The project looked at EMS implementations at several Danish ferry lines, analysing the most important challenges and outlining a suitable implementation strategy. This blog post summarises the key findings.

Crew resistance can negatively affect EMS utilisation

Implementing an EMS on a ship can be perceived as a major change by the crew and can result in crew resistance. Resistance is a natural psychological reaction to innovations that require us to step out of our comfort zones and deliberately change our habits. In case of crew resistance to an EMS, the system does not deliver on its potential because the crew will not use it, or will not use it optimally and consistently.

The reason why this is the case has to do with what an EMS is and what it does – and what it does NOT do. The system shows how much energy is used by onboard equipment, gensets, and engines, and it can analyse how this energy consumption correlates with environmental factors such as wind direction and water depth. This allows the crew to make informed adjustments to make the most of the energy consumed – but they need to actively do so by changing their working and sailing habits, for example by changing course or speed. Unlike power management systems and load sharing features which do not require crew intervention in normal circumstances, EMSes require crews to constantly respond to real-time performance data and take the best possible action. In short: The EMS can point the way towards efficiency improvements, but it is up to the crew to achieve these improvements.

For this reason, crew engagement is absolutely vital in order to avoid resistance and ensure a successful EMS implementation. So, how does management approach this?

Solution: tailor-made change management strategy

There is no universal solution for implementing an EMS. All companies and crews are different and have different organisational cultures. What works on one ship may not work on another, and it is important that management understands the organisational culture on each individual ship before starting the process.

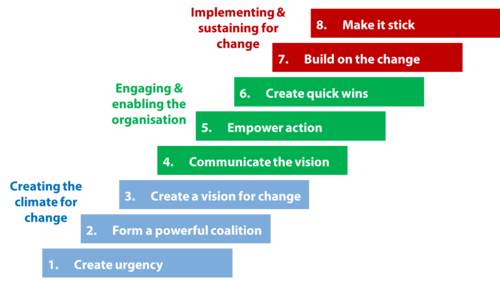

While there is no universally applicable solution, there is a change management model that can be used to develop a tailor-made implementation: Kotter’s 8-step change model. This is a so-called bottom-up approach where employees are involved in the entire change process from discussion and decision to implementation and results. When executed in the right order, and when no steps are left out, the 8 steps of the model define the entire change management process from creating a sense of urgency (defining why the change process is important) to taking action to implement change and making it stick (anchoring the change in the organisational culture). When approached in this way, the process gives the crew a sense of ownership of the change and increases its motivation for actively using the EMS.

The Kotter 8-step model is a tried and tested change management methodology well suited for implementing an EMS on a ship by including the crew in the process. Image source: folmand.com

Vital prerequisites: trust and motivation

Motivation is a vital prerequisite for change management. Successfully implementing an EMS takes hard work from management and crews alike, and this work is not possible without motivation. This is a major reason why management needs to understand the organisational culture of the crew before starting. Are crew members motivated by the knowledge that their efforts can make a positive contribution to the environment? By the desire to perform better? Or by money? When the crew is motivated for change, getting the crew involved in the change management process and reaching the desired results become much easier.

Another important prerequisite is trust. When attempting to introduce new systems that push employees out of their comfort zones, mutual trust between management and crews is vitally important. Open and honest communication is one way of building trust. To take just one example, most crews are very conscious of the fact that their performance is being logged in the EMS. Management must make it perfectly clear how this information will be used, and it must keep all promises made – for example reassurances that crews do not risk disciplinary action, or being fired, as a result of unsatisfactory performance data from the EMS.

Recommendations

- The following recommendations sum up the major findings from the graduation project. They provide a good initial check list before starting an EMS implementation process:

- Understand the culture: It is easier for management to lead change if it is familiar with the organisational culture on the ship and can predict crew reactions to change.

- Create trust: When there is a trustful relationship between management and crews, crew confidence in management decisions is improved.

- Build motivation: If the crew is not motivated, the change process cannot be successful. Motivation is a key driving factor.

- Use a bottom-up strategy: When the crew is involved in the change and feels a part of the project, the change will result in lasting behaviour change.

- Follow the Kotter 8-step process: The Kotter process helps management avoid critical mistakes during the change process.

Useful tips

The following tips come from ferry companies that have successfully implemented an EMS. They are provided here as a source of ideas:

- In one successful EMS implementation, the EMS was installed and started logging voyage data immediately. The crews, however, did not have access to the data until six weeks later, at which point they got access to real-time data and were able to see that the system could indeed help them save fuel. This was very motivational for the crew.

At one company, the crews were given no formal introduction to the EMS but were invited to explore the features and interface of the EMS on their own. Figuring out the features of the EMS (which featured a very user-friendly interface) contributed to crew engagement with the solution. - Management may be able to engender a healthy spirit of competition between crews; this happened with at least one ferry company following the installation of an EMS. When successful, this is a good way of building and retaining motivation.

Conclusion

Implementing an EMS on a ship can be an important step on the way towards reducing vessel fuel consumption and emissions, but benefits cannot be achieved automatically. For companies and crews willing to make the effort, however, a structured change management process based on the Kotter 8-step model and a good understanding of the company culture is a good way of realising the potential of the EMS. Hopefully, the findings of the graduation project will inspire you to define a process that gets your crew involved and helps you overcome resistance in your organisation.

Read more about the Blueflow EMS

Check out our blog post on asymmetrical load sharing (ALS)

Download our FREE whitepaper on ways to save energy and fuel on your ship

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark