Optimum genset operation with asymmetrical load sharing

With the built-in asymmetrical load sharing feature (ALS) of the PPM 300 controller, you can define fixed load set points for one or more gensets, letting them run in optimum conditions. As a result, you get optimised genset performance which can lead to fuel savings, reduced maintenance requirements, and cleaner emissions. The ALS feature can be used in a DEIF PPM 300 power management system with two or more controllers.

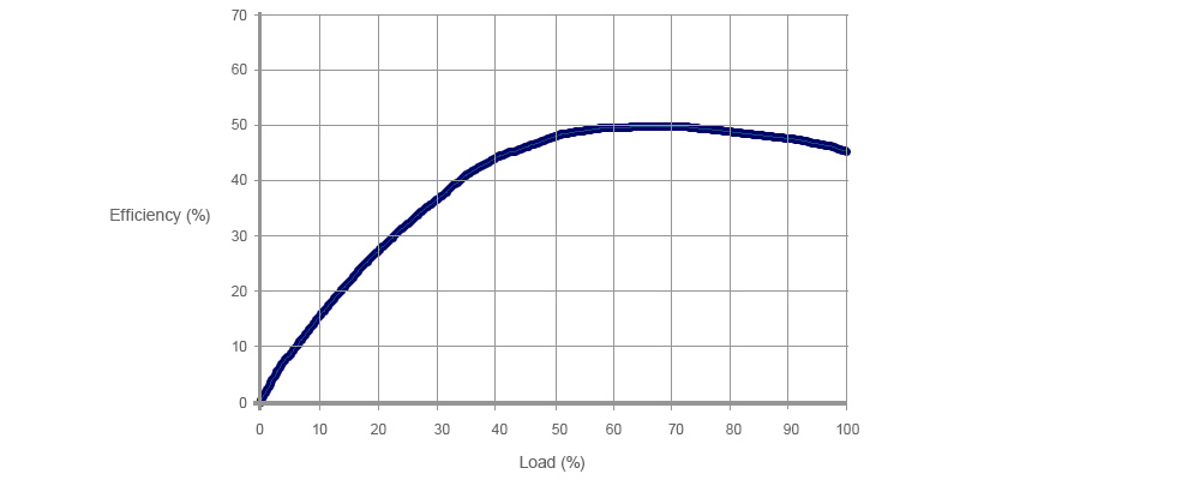

When you want maximum efficiency from your genset, you need to run it at its optimum operational point. This can be tricky, even with multiple gensets: with traditional, equal load sharing, the load at any given point in time will be distributed equally across your gensets without considering their optimum operational points.

If you are using the advanced DEIF PPM 300 protection and power management controller, however, you can use the built-in asymmetrical load sharing (ALS) feature to distribute the load asymmetrically across your gensets. This means that you can run one or more of them at their optimum operational points independently of the load on the remaining gensets.

How does ALS work?

When you have enabled ALS on your PPM 300, you can select a load set point for one or more gensets, depending on the number of gensets running. The gensets will run at the selected load set points whenever possible (see below). There must always be one genset to provide remaining required power or to handle fluctuating loads. In other words: In a system with two gensets, you could define a power load set point for one genset, and if you had three gensets, you could define a load set point on two gensets – and so on. The PPM can be configured to carry out ALS for both active (P) and reactive (Q) power loads.

ALS allows you to define set points that suit your particular genset engines. If you have one engine that is running best at 80% load and another that is running best at 60%, for example, you can define these loads as set points using ALS (provided that you have a third genset available to handle the rest of the total load as described above). Refer to your engine manufacturer’s specifications and the engine operational history to find the optimum operational point.

Requirements

There are a couple of requirements that must be met for ALS to work:

- There must be enough load on the system to actually load the genset(s) with the fixed load and (if necessary) the genset with the fluctuating load. If the load exceeds the defined safety margins, the system will automatically switch to equal load share.

- ALS requires a DEIF power management system of networked, compatible controllers. In other words, each genset included in ALS must be controlled by a PPM 300 with ALS enabled.

You can read more about the advantages of power management systems in our blog post on power management.

Benefits from using ALS

Given the fact that diesel costs usually account for well over half of the total operating expenses of running a genset, using the built-in ALS feature on the PPM 300 could quickly prove to be well worth the effort. Enabling and setting up ALS on your PPM 300 does not take long but can provide significant fuel savings.

When you provide optimum operating conditions for ALS-enabled gensets, you can also prolong their service life, reduce the need for maintenance and repairs, and minimise the risk of operational issues. In addition, as the combustion process is most efficient at the optimum operational point, you achieve the cleanest possible emissions, helping you comply with emissions regulations.

Tip! Did you know that you can customise your PPM 300 without writing a single line of code? Check out our blog post on the free and user-friendly CustomLogic tool .

-

Contact us to discuss your options

- 90 years of energy pioneering

- Manufactured at the highest standards

- Superior quality

- Unmatched service and support

- Made in Denmark