Take control of your O&M strategy with retrofit control solutions

You can’t optimise the wind. And you can’t control government subsidy schemes or other political factors. What you can control and optimise is your wind farm. And the better you do so, the more you can increase AEP and capacity factor, lower O&M costs and achieve a favourable LCOE that translates into shareholder value.

Seize the opportunity at EoW

Service and maintenance costs are a major driver of O&M costs and a significant contributor to the LCOE of your wind farm. Lowering these costs is a key aspect of optimising wind farm operations. As long as you are still covered by OEM warranty, however, there is little you can do to drive down costs. The OEM often has a great deal of control of service and upgrade work for your turbines, and any unauthorised work will be in breach of warranty terms.

When EoW approaches for your wind farm, it can be a welcome opportunity to take full control of your O&M strategy and wind farm management. And one of the most cost-effective paths to full control is a retrofit control solution from a third-party vendor such as DEIF.

Freedom of choice, and a few problems solved

The OEM is often the only company capable of carrying out service and maintenance work on original turbine equipment such as the controller and pitch system. By replacing these components with custom-made retrofit control solutions from a third-party vendor, you get an updated and upgraded solution that can be serviced by multiple parties. This gives you the freedom to take full control of your O&M strategy. The decision to keep using the OEM, select an ISP or go for an in-house service solution is yours to make when you select a retrofit control solution for your wind farm.

By opting for a universally serviceable solution, you solve a few O&M related issues into the bargain. For example, procuring spare parts can be expensive and difficult if the OEM is the only source of parts, especially as turbines get older. OEMs often do not allow access to the turbine controllers or provide software updates, because they want to protect data and intellectual property rights. Service and maintenance procedures for OEM equipment may require the use of proprietary OEM tools. Finding adequate technical documentation for service work can be a challenge. And limited access to wind farm performance data (because you are tied to OEM programs, or because older controllers simply do not generate the data you need) means that you have no access to complete and unbiased status and condition information about your wind farm.

With a retrofit control solution that can be accessed and serviced by several parties, these problems are solved, and you are free to pursue whichever O&M strategy you see fit, driving down O&M costs and optimizing LCOE.

New technology improves turbine performance

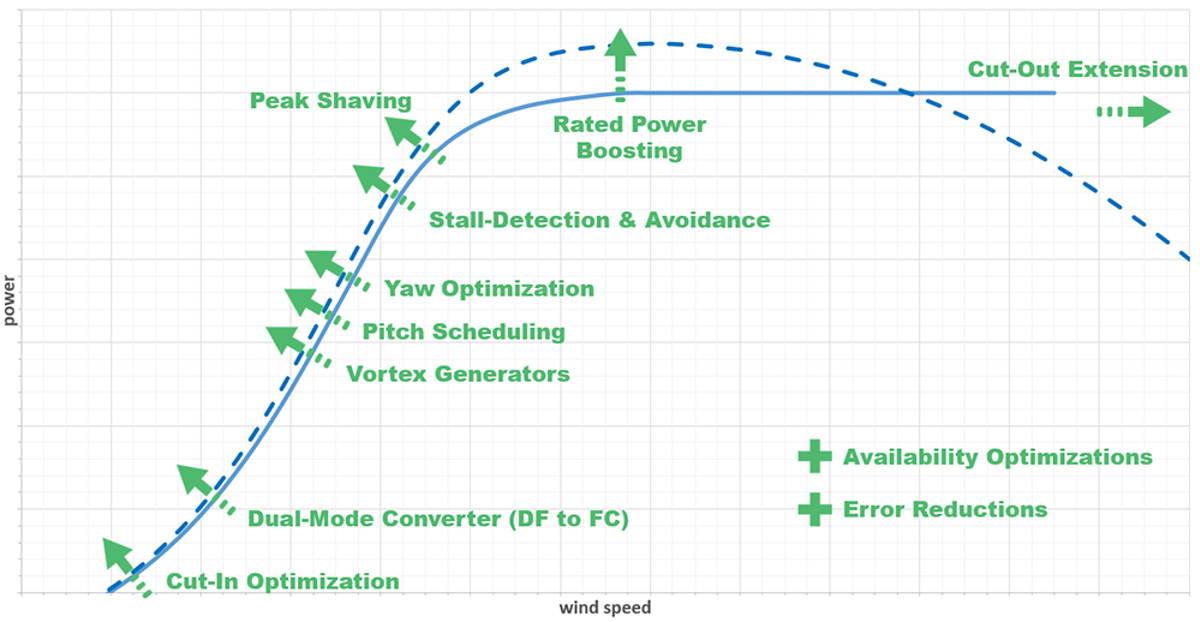

In addition to this freedom, retrofit control solutions also help you increase AEP by improving turbine power performance. When you replace the original OEM control components in your wind turbine with a state-of-the-art retrofit control solution, you get advantages that just weren’t possible when the turbine was commissioned. Retrofitting control solutions can significantly impact turbine performance across the power curve by improving part-load efficiency, increasing nominal power output and extending the range of operation by increasing the cut-out speed.

In short, a retrofit control solution makes you independent of OEM constraints, allowing you to opt for any O&M strategy, and it improves the performance of your wind farm. The key is to select a retrofit control solution from a third-party vendor such as DEIF that does not require special tools and comes with full manufacturer support and full access to performance data, no matter who owns and runs the wind farm.

Let’s talk retrofit solutions!

At DEIF, we don’t sign exclusive deals with anyone. Our priority is to keep your wind farm running at maximum AEP and a favourable LCOE, and we are prepared to support you with the information and data you need to achieve that goal, no matter which turbine brand or model you are using, and no matter how you intend to handle O&M after EoW.

DEIF is a family-owned company headquartered in Denmark, sometimes referred to as the wind power capital of the planet. Our family of partners and customers is truly global, though, and we are active in many markets around the world. Contact us to get more details on how our retrofit control solutions for wind farms can help you take control of your O&M strategy to really control and optimise your wind farm. (When it comes to controlling those political factors, though, you’ll need to look elsewhere.)

We look forward to helping you!